This morning I went to see the progress on some of the metalwork for our house. I love the fineness of metalwork, the crisp lines and economy of material, and the way it can bear the marks of how it was made. We’re using steel for a number of internal and external elements to provide a contrast with the chunkier oak structure and linings. Two metalworkers are making things for the house as there’s quite a lot of it and everyone seems to be busy despite the recession. These photos were taken atCastle Welding.

The photo above shows a row of jigs for making curtain pole finials. I love the way they look so crude yet their function is to make something very accurately. Around them is a vast workshop full of archaic looking contraptions that owner Julian Wittleton has collected at sales and auctions. Some of them look like relics but they are precision tools that can do all sorts of useful engineering tasks. This one is the longest guillotine blade sharpening machine in the southwest:

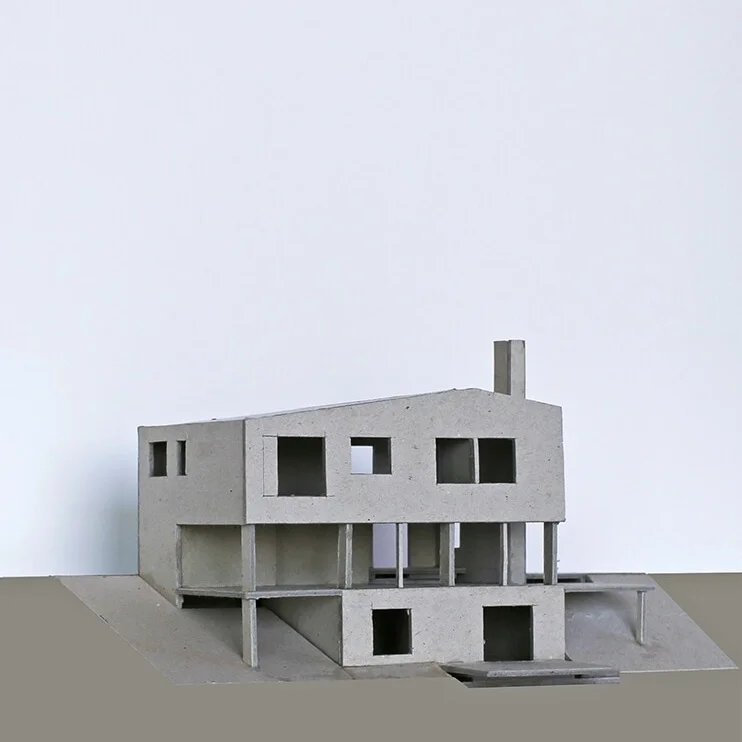

For our house we wanted the internal steelwork to be dark but not with a painted finish which would be too flat. Mild steel comes with a black coating on it called mill scale that is a result of the hot rolling process. The scale protects the steel from corrosion until it is worked and it is removed prior to painting to give a smoother finish. We really like the texture and variation in colour that the scale gives. Where the metal has been welded or bent the scale flakes off but in other places it remains as a crusty layer. By applying a clear powder coating the look of the raw steel can be preserved. These are some internal glazing frames for our house:

One of them has an opening light and we designed a little handle for it: